ITERAMS -project - reinventing the role of water and waste in mining

Ima Engineering is taking part in the EU-funded project ITERAMS, "Integrated Mineral Technologies for More Sustainable Raw Material Supply".

The ITERAMS consortium met in Pori, Finland, 1-2.6.2017 in order to kick off the three-year project, which will run until 31st May 2020. The consortium with 16 partners coordinated by VTT Technical Research Centre of Finland is multidisciplinary covering well the disciplines of geology, mining, minerals processing, microbiology, thermodynamics, chemistry, water and environmental sciences, sustainability, process modelling and simulation in a close cooperation between academia and industry.

Partners discussed main technical issues through the presentation of the activities in each WP. Work to be done during the first semester of the project was scheduled. Outotec hosted the kick-off meeting at its research centre in Pori, where partners also had the possibility to attend the laboratory and pilot plant tour.

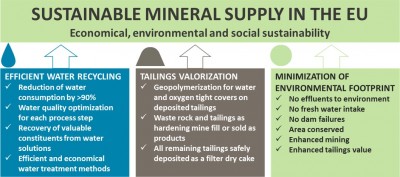

The EU Horizon 2020 ITERAMS -project intends to reinvent the role of water and waste in mining. The project targets at significantly reducing water consumption by circulating process waters as well as the amounts of tailings waste through valorization of the mineral matrix. Developed water and waste efficient concepts will be jointly validated by industrial and research partners at partners’ mine sites in Finland, Portugal and either in Chile or South Africa.

Created knowledge is used for the industrially relevant water recycling testing protocol development. New developed holistic water and waste concepts and systems result in higher technical, economic, and environmental performance in raw materials production. After ITERAMS, the EU has the potential to be in the forefront with regard to minimal wastes, minimal energy and minimal water consumption in the mining sector.

You can read the original press release here.

What is IMA Engineering?

IMA Engineering has used on-line sensors for analyzing ore and waste rock in mining for over 25 years. Today IMA on-line sensors are used in various stages of the mining process including on-line analysis of drill cores, drill chips, ore, and waste in loader buckets, ROM ore analysis on conveyor belts and in bulk ore sorting, as well as slurry analysis in concentrators.

Book a time to talk to one of our experts. Follow us on Twitter and LinkedIn and stay up-to-date with the latest IMA news.