The benefits of ore sorting and sensing in mining

Ilpo Auranen, Chairman of IMA, has been recently interviewed by the International Mining Magazine on the topic of ore sorting. In this interview, Ilpo talks about the benefits of ore sorting and sensing in the mining industry, sharing a success story from an iron mine in Brazil.

IMA Engineering - a successful example of the Finland Innovation

IMA Engineering will be present in “The Key to Success of the Finland Innovation Ecosystem” webinar cooperation with Chilean companies. After Nicolaides, IMA’s partner in Chile, set up and run a successful IMA FCA pilot for the largest iron producer in the South American country, IMA also becomes a successful example for the Finnish innovation ecosystem.

IMA Fast Conveyor Analyzer pilot in iron mine in Chile

2022 has started on a high note with great news from our partners and customers in South America. Our local partner in Chile, Nicolaides has done an amazing job in setting up and running a successful IMA FCA pilot with Compañía Minera del Pacífico (CMP), the largest iron producer in Chile.

IMA Smart Mining Solutions in 2021

There is no doubt that 2021 was an interesting year for everybody. During this month we take some time to count our achievements and learn how we can further improve and serve the world. We also produced and launched our solutions video this year, to better illustrate how IMA Smart Mining Solutions work together to improve mining efficiency and reduce mining costs. For more IMA Smart Mining Solutions please visit our YouTube Channel.

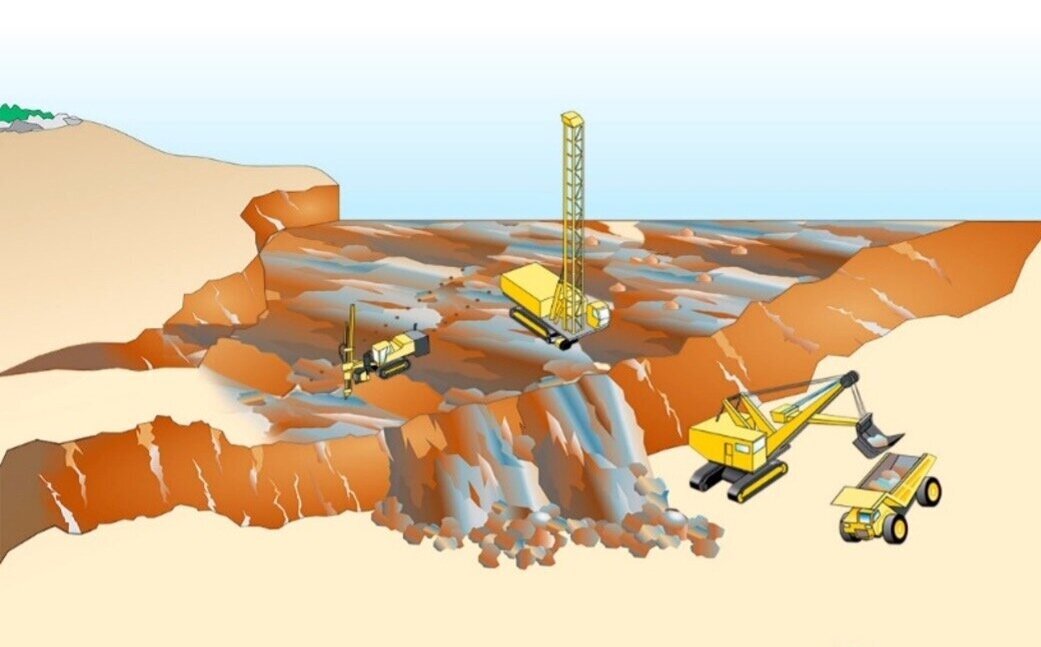

Economics of pre-concentration in mining: Bulk Ore Sorting in a copper mine

Pre-concentration by Bulk Ore Sorting (BOS) has gained interest in the mining industry over the past few years due to its environmental and economic benefits. The BOS method is utilizing reducing natural rock heterogeneity in separating the waste rock from the ore before it enters energy intensive grinding and mineral processing process.

We are hiring | Technical Sales Support Specialist, Espoo

We are looking for a Technical Sales Support Specialist for IMA Engineering, a manufacturer of mining innovations. In this role, you will be working within the company’s international projects, reinforcing their technical sales and marketing. You get to be a part of a tight, growing work community. If you seek variety, possibility to have an influence and the freedom to work either from the Espoo office or remotely from home, this might be the job for you!

Reducing carbon footprint in mining by bulk ore sorting

Sustainability and environmental consideration stand at the core of IMA’s philosophy. Everything we do is to help mines become more efficient and environmentally sustainable. In Bulk Ore Sorting the IMA BOSS is removing waste rock from mineral concentrator feed material and replacing it from ore recovered by sorting from waste rock.

Remote installations and reduction in CO2 emissions

With the ongoing COVID-19 crisis, we have reduced and, in many cases, halted completely our travel plans to visit our customers. We worked hard to transform and adapt to the new global economical and environmental situations, and this led to remote deliveries and installation of our smart mining solutions. This month we delivered and installed the IMACON remotely in Peru. Our solutions are installed and used in a copper mine.

Sampling and Analysis Solutions for Mine Grade Control

IMA Smart Mining Solutions was recently invited to write an article on sampling and analysis solutions for Africa Mining Insight. The article discusses and highlights the benefits the IMA Smart Mining Solutions core products have for the mining industry.

IMA Engineering is moving... forward!

As you might have heard, IMA Engineering is moving. Yes, we confirm that! We outgrew our house, so there wasn't enough space.

IMA Autosampler is going underground

Last week, we talked about how companies use it all around the world, in different mining applications. Now, we take the Autosampler underground. The IMA Autosampler drill cuttings sampling, splitting and bagging device which has been used in surface drilling applications all over world has found a new application in drilling.

The Autosampler used globally in different mining applications.

Earlier this year we introduced The Autosampler - A new IMA product for drill chip sampling and now we have a few exciting updates regarding product deliveries and demand. You can read more about the IMA Autosampler, its features and benefits here.

Autonomous Sampling and Analysis Solutions

Mr. Ilpo Auranen, Chairman of IMA Engineering has been recently interviewed by Dan Gleeson from the International Mining Magazine on the topic of Autonomous Sampling and Analysis Solutions. You can read the article featuring Mr. Auranen’s interview in the 2021 May issue of the International Mining Magazine. Read the interview online or download a copy.

Delivering Smart Mining Solutions to Remote Locations

Since the beginning of 2021, we have seen an increase in demand for our data driven mining technology, especially for IMACON and conveyor belt applications (BOSS – Bulk Ore Sorting System). This month we are delivering and remotely installing IMACON and conveyor applications solutions in Peru, Chile and South Africa.

Digital and Sustainable Ore Sorting Solutions

Mr. Ilpo Auranen, Chairman of IMA Engineering has been recently interviewed by Dan Gleeson from the International Mining Magazine on the topic of Ore Sorting and Pre-Concentration Technology. You can read the whole article featuring Mr. Auranen’s interview in the 2021 March issue of the International Mining Magazine. Read the complete article and interview online or download a copy below.

Benefits of On-line Grade Control - Case Study

IMA Engineering carried out grade control study in a low grade nickel mine, utilizing the new Percussive Drill Sampler - Analyzer (PDSA) trailer mounted version. The goal of the study was to compare the current mine grade control method with the new continuous On-Line sampling and analysis method, and calculate it’s effect to the mine economy.

Autonomous Digital Mining Application - Blast Hole Sampling

This week, we continue our series of posts on the topic of Blast Hole Sampling and Analysis in Ore Grade Control in Mining and today we are talking about IMA Engineering’s Methods, Equipment and Results for Blast Hole Sampling. This article and the attached white paper are the continuation of our previous article that you can read here.

The Importance of Sampling and Analysis Accuracy in Grade Control

Blast hole sampling and analysis in Ore Grade Control in Mining is a topic that we feel, hasn’t been covered enough. During the month of March 2021, we aim to bring some clarity on this topic and to present some solutions to the current challenges faced by mining companies all over the world.

The Autosampler - A new IMA product for drill chip sampling

When working with drill cuttings sampling analysis we noticed that the conventional samplers with riffle and cone type sample splitters that take physical samples from drill chip were not giving good enough representative samples. We thought that there has to be a better way - and came up with the Autosampler, our drill cuttings sampling device.

Sampling and Analysis - International Mining Magazine

IMA Engineering is one of the first companies to integrate X-ray Fluorescence (XRF) technology into the drill core analysis process. Together with our partners from Mine On-Line Service we developed and produced the Nordic region’s first mobile core scanner prototype more than seven years ago. Ilpo Auranen, Chairman of IMA Engineering, has been recently interviewed by the International Mining Magazine on the topic of drill core analysis.